Introduction

The NJ series of Machine controllers introduced built in motion control engines. This simplified machine design by incorporating functions that once were handled by a separate motion controller and allowed easy sequencing of motion along with the other machine control aspects. These NJ series CPUs have from 0 to 256 "Motion axes".

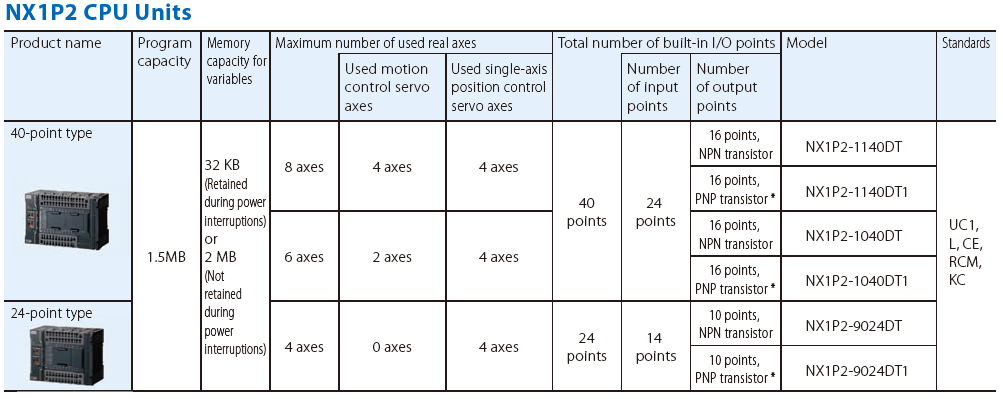

When the NX series of Machine controllers were released (NX1P2, NX102 series etc) a concept called Single-Axis Position Control axes was introduced. All CPUs have axis control, however some of these axes are this simpler Single-Axis type. For instance, below is a table from the NX1P2 brochure that lists the number of total axes, and the type.

Note in the above table, that the distinction is made between Motion axes and Single-Axis Position Control axes.

Motion Axes

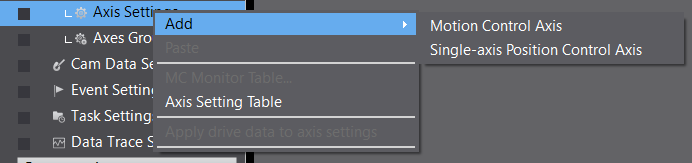

Motion axes are full functionality motion control axes. They allow simple point to point movements such as Move Absolute or Move Relative, as well as coordinated or synchronized motion such as Electronics Gearing, Cams, Linear and Circular Interpolated moves etc. In short, a Motion axis can do anything the Motion toolbox has available. When setting up an axis in Sysmac Studio on a controller that supports both Single-Axis and Motion axes, the user has the ability to set an axis as a Motion Control Axis or a Single-Axis Position control axis.

Single-Axis Position Control Axes

Since many servo control needs are relatively straight forward, it made sense to introduce a simpler axis capability and build this control into all newer models. Where the NJ series were available with 0 axes to reduce costs, the NX series Machine Controllers included axes even on the smallest CPU unit. As a short answer as to what Single-Axis axes are capable of, we can say "independent positioning control functionality". So you could use these axes as a feed into a punch station, for a linear or rotary positioning axis, even as an axis in a gantry.

However as it is independent (not able to be synchronized), in a gantry application which consists of Single-Axis axes, each axis can be moved to a target position, but the system would not be following a linear path; each axis is independently moving to the target. Often this is not an issue, following a linear path is nice to have but not necessarily essential.

Control line electronic gearboxes (a slave axis synchronized to a master via an exact ratio), Cams (a slave synchronized to a master via a profile) etc are not available, basically anything that requires a master axis to operate cannot be used in Single-Axis axes. So a complex profile of a flow wrapper jaw would need to be Motion Control for instance as it requires synchronization to the film web.

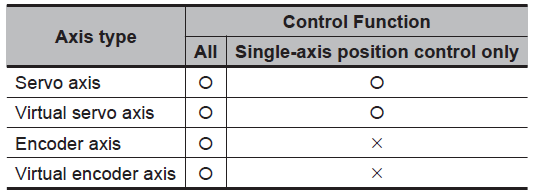

There are four Axis Types in the Sysmac Controllers;

- Servo Axis (a real servo typically connected via EtherCAT)

- Virtual servo axis (an axis that can be moved just like a real axis, but it is not attached to a real servo)

- Encoder Axis (encoder is wired to an Encoder input and the Motion engine is used to scale into real engineering units and can then be used as a master axis for synchronized control, or for any other feedback in programming)

- Virtual encoder axis (not very often used, is a simulated encoder axis only used in place of an encoder axis when there is no physical encoder)

This table shows what Axis Types are available for Single-Axis Position control axes. Note that the Encoder axis type must be a Motion Axis. It is tempting to think that an encoder axis (or half axis as they are sometimes called) could be a Single-Axis Position Control Axis type, but instead must be a Motion Axis.

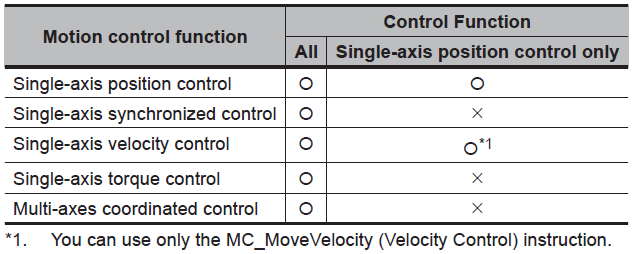

As you will now appreciate, this table shows the functions that are possible for Single-Axis Position Control axes

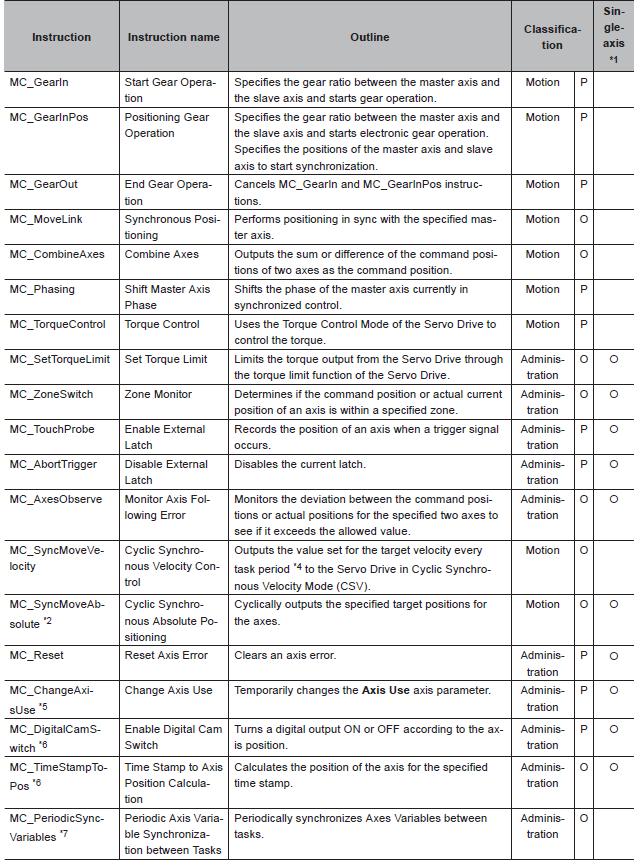

The stand out of this table is Single-Axis Torque control. Again, it would be tempting to assume that Torque control can be applied on a single independent axis and therefore possible with a Single-Axis Position Control axis type, but must be a Motion axis to use this function.

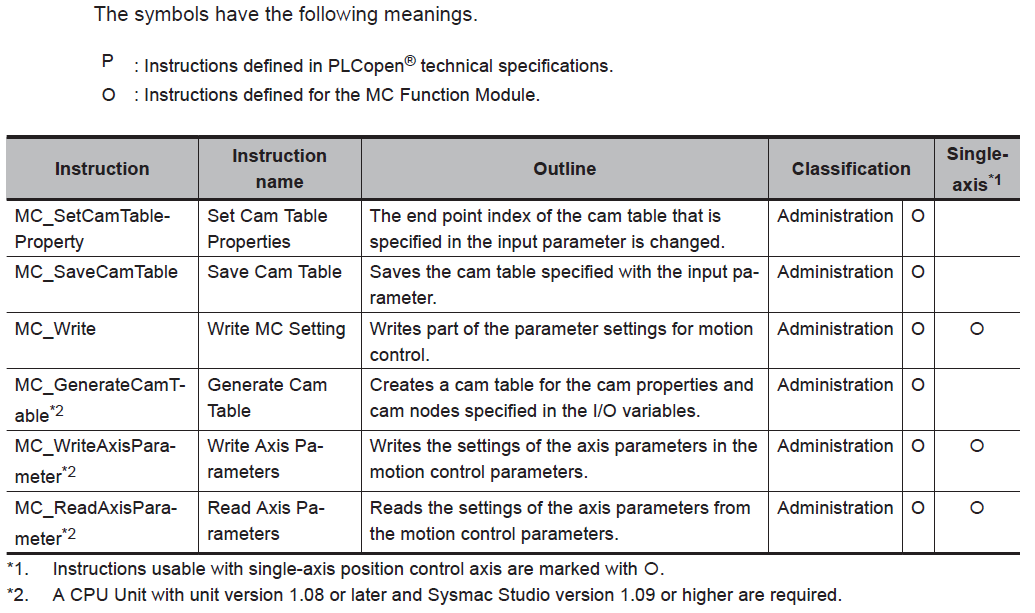

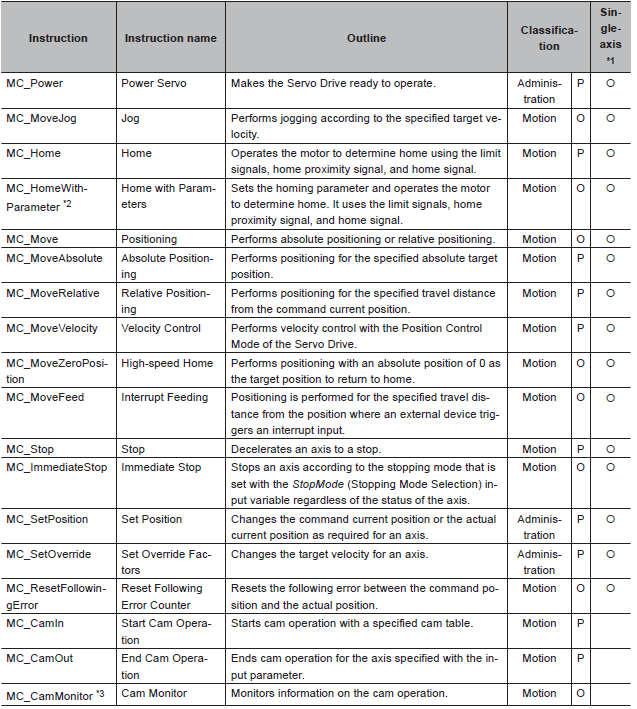

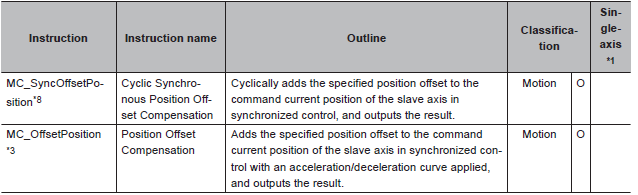

The following tables have been taken from the Instruction Reference manual W508 section 2-2. Note the right hand column which specifies if the axis instruction is available for Single-Axis Position Control axes (Motion axes can execute any instruction). an "O" indicates that instruction is available for Single Axis Position Control axis types.

None of the Axis group instructions are valid for the Single-Axis Position Control axis type, so these instruction tables have been omitted. If you wish to review these instruction types, refer to document W508-E1 section 2-2-3 Axis Group Instructions.

If you wish to discuss your motion control application with OMRON engineers, please get in contact with us, we would be glad to help you design a high performance system to perfectly suit your needs.